A control system is a vital component in various industries and applications, playing a crucial role in managing and regulating processes to ensure optimal performance and efficiency. From manufacturing plants to power grids, control systems are employed to monitor, command, and regulate the behavior of devices and systems.

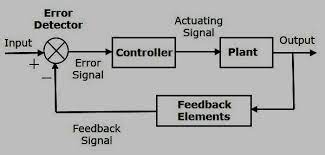

In its essence, a control system consists of inputs, outputs, and a controller that processes information received from the inputs to generate appropriate outputs. These inputs can be sensors that measure variables such as temperature, pressure, or flow rates. The controller then compares these measurements with desired setpoints or reference values.

The control system’s primary objective is to maintain the system’s behavior within predefined limits or achieve specific goals. It achieves this by adjusting the outputs based on the feedback received from the sensors. This process is known as closed-loop control since it continuously monitors and adjusts the system based on real-time information.

There are various types of control systems used in different applications. One common type is proportional-integral-derivative (PID) control. PID controllers use algorithms to calculate appropriate output adjustments based on error signals (the difference between desired setpoints and actual measurements), integrating past errors and considering their rates of change.

Another type is model-based control, where mathematical models of the system are used to predict its behavior and optimize control actions accordingly. Model-based control systems are often employed in complex processes such as chemical reactions or advanced robotics.

Control systems can also be categorized as either analog or digital. Analog control systems use continuous signals for measurement and adjustment, while digital control systems process discrete signals using microprocessors or programmable logic controllers (PLCs). Digital control systems offer greater flexibility, accuracy, and ease of implementation compared to their analog counterparts.

The benefits of implementing a well-designed control system are numerous. It enables precise regulation of variables within tight tolerances, leading to improved product quality and consistency. Control systems also enhance safety by monitoring critical parameters and triggering alarms or emergency shutdowns when necessary. Additionally, they optimize resource usage, minimize waste, and reduce energy consumption, resulting in cost savings and environmental benefits.

In conclusion, control systems are integral to modern industries and applications. They provide the means to monitor, regulate, and optimize processes for improved performance, safety, and efficiency. Whether it’s controlling temperature in a chemical reactor or maintaining stable power supply in an electrical grid, control systems play a vital role in ensuring smooth operations and reliable outcomes.

5 Essential Tips for Effective Control System Design and Management

- Understand the system requirements and objectives before starting the design process.

- Utilize appropriate modeling techniques to accurately represent the system dynamics.

- Design a robust control architecture that is capable of accommodating changes in the system’s environment or parameters over time.

- Validate and verify your controller design to ensure it meets all performance requirements and safety standards before implementation.

- Monitor and adjust your control system regularly to ensure optimal performance over time

Understand the system requirements and objectives before starting the design process.

Before embarking on the design process of a control system, it is crucial to have a clear understanding of the system requirements and objectives. This initial step sets the foundation for a successful and effective control system design.

Understanding the system requirements involves identifying the specific needs and constraints of the system. This includes determining the desired performance metrics, operational parameters, and any regulatory or safety standards that need to be met. It is essential to gather comprehensive information about the system’s inputs, outputs, and expected behavior under different operating conditions.

Equally important is defining the objectives of the control system. What are the key goals you want to achieve? Is it to maintain a stable temperature, regulate pressure within a certain range, or optimize energy consumption? Clearly defining these objectives will guide the design process and ensure that the control system is tailored to meet your specific needs.

By taking the time to understand the system requirements and objectives upfront, you can avoid costly mistakes and rework later in the design process. It allows you to make informed decisions about selecting appropriate sensors, actuators, controllers, and algorithms that align with your goals.

Moreover, this understanding helps in determining whether a simple or complex control strategy is required. For instance, if precise regulation within tight tolerances is necessary, a more advanced control algorithm like PID may be needed. On the other hand, if simpler on-off control can achieve your objectives without compromising performance, it may be a more cost-effective solution.

Furthermore, understanding system requirements and objectives enables effective communication between stakeholders involved in the project. Whether it’s engineers designing the control system or operators who will interface with it daily, having clarity about what needs to be achieved ensures everyone is on the same page.

In conclusion, understanding system requirements and objectives before starting the design process is crucial for developing an efficient and effective control system. It sets clear expectations for performance metrics while considering operational constraints. By investing time in this initial step, you can lay a solid foundation for a successful control system design that meets your specific needs and objectives.

Utilize appropriate modeling techniques to accurately represent the system dynamics.

Utilizing appropriate modeling techniques is a crucial tip when it comes to designing and implementing control systems. Accurately representing the dynamics of the system through modeling allows for better understanding and control over its behavior.

When developing a control system, engineers rely on mathematical models to simulate and predict how the system will respond to different inputs and disturbances. These models capture the relationships between various variables and help in designing effective control strategies.

Choosing the right modeling technique is essential to ensure that the system’s dynamics are accurately represented. Different systems may require different modeling approaches, such as differential equations, transfer functions, state-space models, or even more advanced techniques like neural networks or fuzzy logic.

Accurate modeling enables engineers to analyze the system’s response under various scenarios, identify potential issues or limitations, and optimize control strategies accordingly. It helps in determining appropriate controller parameters and understanding how changes in inputs or disturbances affect the system’s behavior.

Moreover, accurate modeling allows for effective simulation studies before implementing control strategies in real-world applications. Engineers can test different control algorithms virtually, evaluate their performance, and make necessary adjustments without risking any physical equipment or processes.

By utilizing appropriate modeling techniques, engineers can gain valuable insights into the system’s behavior and dynamics. This knowledge forms a solid foundation for designing robust and efficient control systems that can adapt to changing conditions and deliver desired outcomes.

In summary, accurate representation of system dynamics through proper modeling techniques is a crucial tip for successful control system design. It enables engineers to understand how the system responds to different inputs and disturbances, optimize control strategies, and simulate various scenarios before implementation. By following this tip, engineers can develop reliable and effective control systems that meet performance objectives while ensuring stability and efficiency.

Design a robust control architecture that is capable of accommodating changes in the system’s environment or parameters over time.

When designing a control system, one crucial tip to keep in mind is to create a robust control architecture. A robust control architecture refers to a system that can adapt and accommodate changes in the environment or parameters of the system over time.

In many real-world scenarios, the conditions and parameters of a system are not static. They can vary due to factors such as external disturbances, equipment aging, or changes in operating conditions. To ensure the control system’s effectiveness and stability, it is essential to design it in a way that can handle these variations without compromising performance.

One way to achieve this is by incorporating flexibility into the control architecture. This means designing the system with sufficient degrees of freedom and adaptability. By considering potential changes and uncertainties during the design phase, engineers can develop control strategies that can adjust and respond accordingly.

A robust control architecture typically involves several key elements:

- Sensing and Monitoring: Implementing sensors to gather real-time data about the system’s parameters and environment. This information provides valuable feedback for making informed control decisions.

- Feedback Control: Using feedback loops to continuously compare desired setpoints with actual measurements. By constantly monitoring and adjusting based on this feedback, the control system can maintain stability even when faced with changing conditions.

- Adaptive Control: Incorporating adaptive algorithms or techniques that allow the control system to learn from experience and adjust its behavior accordingly. Adaptive control enables the system to adapt its parameters or strategies in response to variations in the environment or system dynamics.

- Fault Detection and Diagnostics: Integrating mechanisms for detecting faults or anomalies within the system itself. This helps identify any deviations from expected behavior promptly, allowing for timely corrective actions.

By designing a robust control architecture that considers potential changes in environmental conditions or parameters over time, engineers can ensure that their systems remain effective and reliable throughout their operational lifespan. This approach enhances stability, performance, and resilience against uncertainties, ultimately leading to improved overall system performance.

In summary, a robust control architecture is critical for accommodating changes in a system’s environment or parameters over time. By incorporating flexibility, feedback control, adaptability, and fault detection mechanisms, engineers can design control systems that can effectively handle variations and uncertainties while maintaining stability and optimal performance.

Validate and verify your controller design to ensure it meets all performance requirements and safety standards before implementation.

Validating and verifying your controller design is a crucial step in the development of a control system. This process ensures that the design not only meets the desired performance requirements but also adheres to necessary safety standards before implementation.

Validation involves testing the controller design using simulation tools or hardware prototypes to assess its performance under various operating conditions. By subjecting the design to different scenarios, engineers can evaluate its responsiveness, stability, and ability to meet setpoints or reference values accurately. This step helps identify any shortcomings or areas for improvement in the controller’s functionality.

Verification, on the other hand, focuses on confirming that the controller design complies with safety standards and regulations. Safety is of utmost importance in control systems, especially in critical applications such as aerospace, healthcare, or nuclear power plants. Verification involves analyzing potential risks and hazards associated with the control system and ensuring that appropriate safety measures are implemented to mitigate them.

By validating and verifying your controller design before implementation, you can prevent costly errors or failures in real-world applications. It allows you to fine-tune your design based on performance feedback and address any safety concerns proactively. This approach ensures that your control system operates reliably, efficiently, and safely once deployed.

Moreover, validation and verification provide confidence in your controller’s capabilities and help build trust among stakeholders such as clients, regulatory bodies, or end-users. Demonstrating compliance with performance requirements and safety standards enhances credibility and facilitates smoother integration into existing systems or processes.

In summary, validating and verifying your controller design is an essential step in control system development. It enables you to ensure that your design meets all performance requirements while adhering to necessary safety standards. By conducting thorough testing and analysis upfront, you can identify potential issues early on and make necessary adjustments before implementation. This approach not only improves overall system performance but also instills confidence in stakeholders regarding the reliability and safety of your control system.

Monitor and adjust your control system regularly to ensure optimal performance over time

Regular monitoring and adjustment of a control system is crucial to maintaining its optimal performance over time. Just like any other system, control systems can experience changes, drifts, or wear that can affect their accuracy and effectiveness. By implementing a proactive approach to monitoring and adjusting, you can ensure that your control system continues to operate at its best.

Monitoring involves regularly checking the inputs, outputs, and overall performance of the control system. This can be done through data logging, trend analysis, or real-time monitoring tools. By keeping a close eye on the system’s behavior, you can identify any deviations or abnormalities early on.

Adjustment refers to making necessary changes or corrections to the control system based on the monitoring results. This may involve recalibrating sensors, updating setpoints or reference values, or fine-tuning controller parameters. The goal is to bring the system back into alignment with its desired performance standards.

There are several reasons why regular monitoring and adjustment are essential for control systems. Firstly, external factors such as environmental conditions or equipment degradation can impact the accuracy of measurements or introduce errors into the system. By monitoring regularly, you can detect these changes and take corrective actions promptly.

Secondly, internal factors like component aging or software glitches may affect the control system’s performance over time. By adjusting parameters or conducting maintenance tasks as needed, you can prevent these issues from compromising the overall functionality of the system.

Thirdly, regular monitoring and adjustment help optimize energy usage and resource efficiency. Control systems that are not properly calibrated may lead to unnecessary energy consumption or wastage of resources. By fine-tuning the control settings based on real-time data, you can achieve better efficiency and cost savings.

Lastly, regular monitoring and adjustment contribute to overall process improvement. By analyzing trends and patterns in the control system’s behavior over time, you can identify areas for optimization and implement continuous improvement initiatives.

In conclusion, if you want your control system to perform optimally over time, it is crucial to monitor and adjust it regularly. By staying vigilant and proactive, you can detect and address issues early on, optimize resource usage, and continuously improve the system’s performance. Remember, a well-maintained control system leads to better outcomes, increased efficiency, and ultimately, a competitive advantage in your industry.